》Jingcheng Mold:

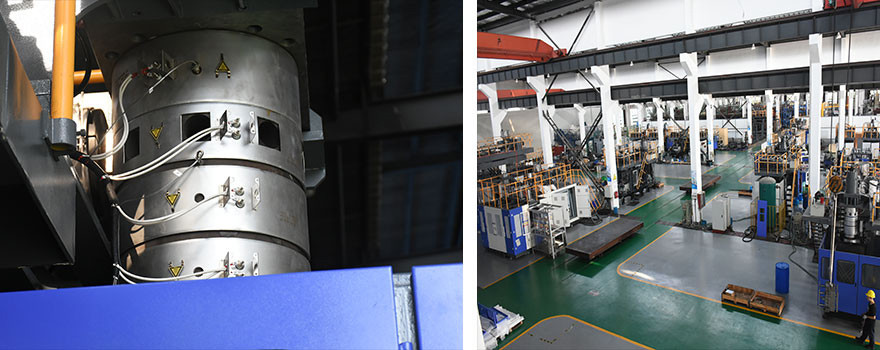

China Jingcheng Times Group, founded in 1996, the current registered capital of 108 million RMB, the main products are extrusion flat die head, multi-layer co-extruded composite distributor, melt metering pump, filter and other related products, since the establishment of the company, the production of various types of high and mid-range die head more than 9000 sets.

》Application project: Jingcheng mold thermocouple. Thermal resistance temperature sensor project

User application requirements: die head mold, melt-blown fabric equipment, extruder, bottle blowing machine, injection molding machine and automation equipment mold temperature sensing system solution needs to be solved, mold temperature measurement requires fast response speed, accurate temperature measurement, long-term 350-400 degrees temperature, 24 hours of work, the use of harsh environment, long quality life, do not want to replace often.

》Hequan analysis reasons and solutions:

Hequan went to the site to understand the application of the user, and did analysis and design, for each device requirements of the user, to provide the corresponding temperature sensor products, to meet customer requirements, the industry is also the only warranty more than 2 years, so that users can apply our temperature sensor not only greatly improved in quality, but also only one-third of the cost of imports. It also saves time. So that users are very satisfied, while widely recognized in the industry.

》Customer effect:

Mold temperature measurement response speed is fast, temperature measurement is accurate, long-term 350-400 degrees temperature, 24 hours of work, can also be used in harsh environment, long quality life.

Hequan thermocouple adopts imported temperature measuring wire, the thermal resistance adopts German Horace core, the wire adopts Taiwan original wire, the product adopts imported technology and test equipment factory testing, and we can analyze the on-site problems for users and develop the required products to meet the assembly requirements and temperature measurement requirements for each customer. In the plastic machinery industry (injection molding machines. Blow molding machine. Extruder. Melt-blowing equipment, mold industry, Hequan technology focus on industry technology, research and development and manufacture of precision and high-end thermocouples, thermal resistors, solid-state relays, temperature control instruments for the industry, from temperature measurement to sensing, to control, to provide one-stop temperature control solutions. At present, it has been widely used and recognized in the industry, and its cooperative users are: Jingcheng mold, Wanlian mold, Taiwan Fengtie, Yizhi Secret, Jinwei Machinery, Nanjing Keya, Jiangsu Vida and other leading enterprises in the industry. Products with CE certification, patent.